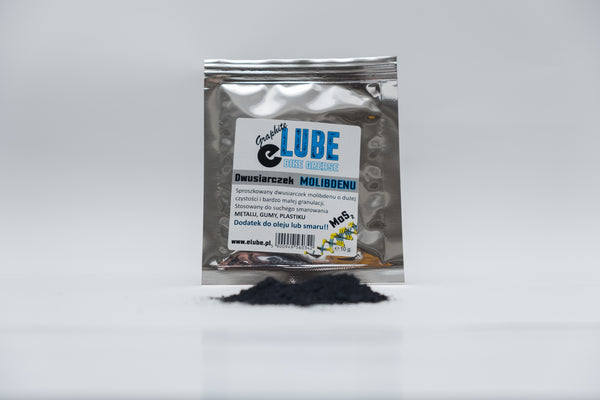

Molybdenum disulfide MoS2

Molybdenum disulfide MoS2 powder (granulation up to 3-4μm according to Fisher)

Molybdenum Disulfide Evil Lubricants Pure, Selected, Ratified MoS2 Powder

Production of molybdenum disulfide

Molybdenum disulfide is a mine product. Molybdenite ore is processed by flotation to give relatively pure MoS2, the main impurity being carbon.

Molybdenum disulfide is an inorganic compound with a hexagonal layered structure, composed of molybdenum and sulfur. Its chemical formula is MoS2.

It is a universal black powder used mainly as an anti-friction and anti-wear additive.

Molybdenum competes with other solid media, primarily graphite and hexagonal boron nitride. Due to its low friction properties, which are superior to those of graphite, as well as its high load-bearing capacity and the fact that it is relatively non-reactive, resistant to dilute acids and oxygen. MoS2 does not depend on adsorbed water or other vapors for its lubricating properties.

Applications Applications

- Lubricant additive

- Additive to oils

- Polymer additive

- Addition to other sliding coatings

- desulfurization catalyst in petrochemistry

- for the production of hydrogen for use in fuel cells

- for semiconductor production

Application in lubricants

Molybdenum disulfide can be used at temperatures up to 450 ºC in oxidizing environments and up to 1100 ºC in non-oxidizing environments. Its stability makes it useful in high temperature and high vacuum applications where other conventional greases and oils fail.

MoS2 is used as an anti-friction coating for applications where load capacity, operating pressure and low coefficient of friction are paramount. This coating provides effective lubrication over a wide range of loads, in many cases exceeding 250,000 psi. Molybdenum coatings lubricate sacrificially, transferring lubricant between two mating surfaces, helping to reduce wear and coefficient of friction.

Coatings with molybdenum disulfide (MoS2) create a so-called dry lubricating film.

Molybdenum disulfide is often a component of compounds and composites where low friction is desired. Molybdenum disulfide is found in many oils and greases because greases with its addition retain lubrication even in cases of almost complete loss of oil, the so-called "dry lubrication", and thus find use in critical applications such as automotive and aviation engines.

When added to plastics, molybdenum disulfide provides a composite with improved strength as well as reduced friction.

Application in petrochemistry

Synthetic molybdenum disulfide is used as a desulfurization catalyst in refineries, hydro-desulfurization.

Application in automotive industry

Molybdenum disulfide MoS2 is used as an additive to engine and transmission oils. (Recommended smaller granulation 0.85 μm - available as a second product >>>)

Advantages of use:

- It significantly reduces friction, preventing so-called cold starting.

- Quiets the operation of the engine or gearbox

- Fills micro-pitting on the piston-cylinder connections.

- It will reduce combustion because the resistance during engine operation is lower.

- Reduces engine wear and extends its life.

Properties of Molybdenum Disulfide

- Composition: Molybdenum disulphide

- Formula: MoS2

- CAS: 1317-33-5

- CE: 215-263-9

| Property | Value result |

| Particle Size (Fisher Number) | up to 3-4 μm |

| Contents | Max % by tue |

| undissolved acids | 0.5 |

| iron | 0.4 |

| Molybdenum Trioxide | 0.05 |

| Water | 0.05 |

| Oil | 0.4 |

| Coal | 1.5 |

| Acid number (TAN) | 0.25 |

Product title

Vendor

19,99 zl PLN | 24,99 zl PLN

Product title

Vendor

19,99 zl PLN | 24,99 zl PLN

Product title

Vendor

19,99 zl PLN | 24,99 zl PLN

Product title

Vendor