Sort + Filter

Lubricants for Electric Motors

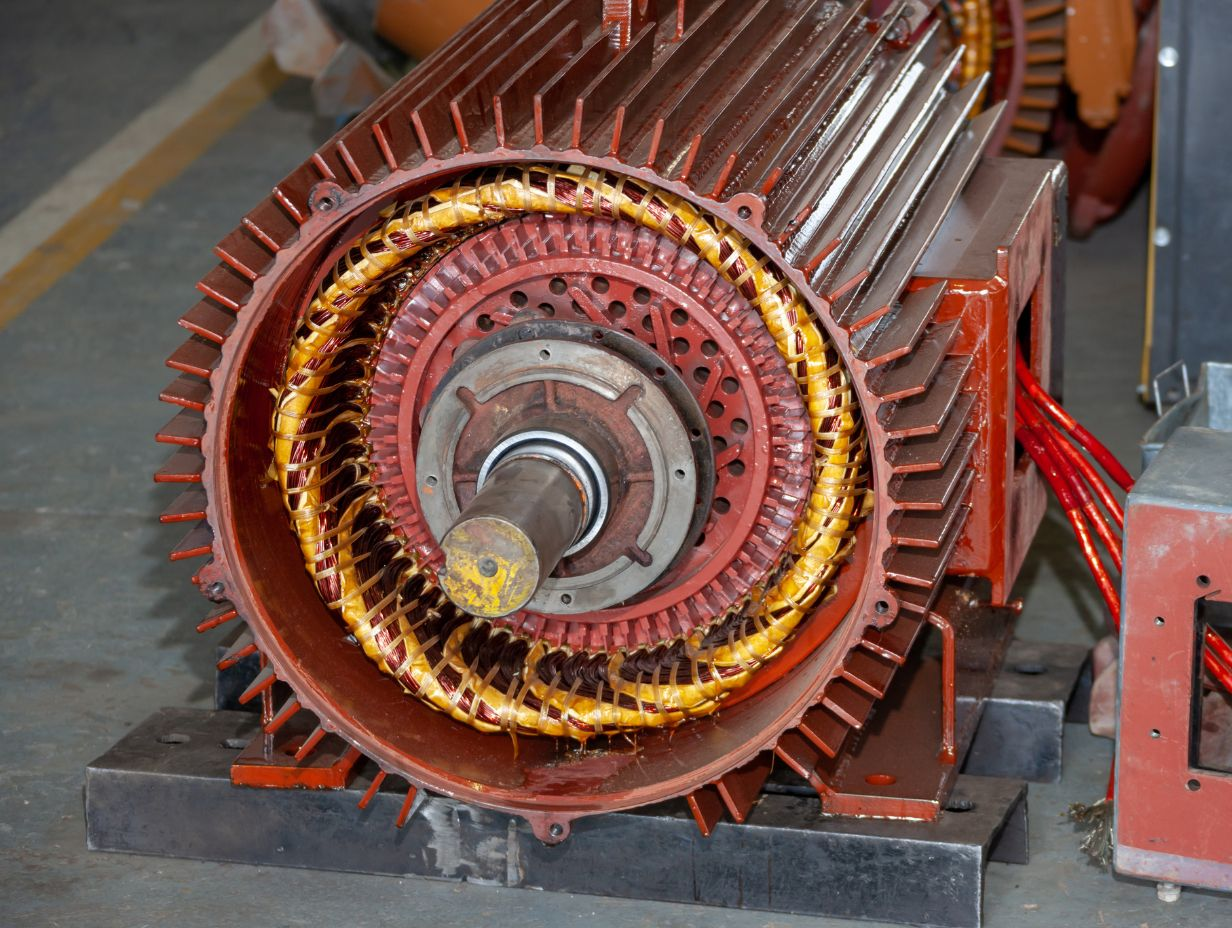

An electric motor is a device that converts electrical energy into mechanical energy.

Electric motors require proper lubrication to provide the performance required by the plants. They usually operate in harsh conditions, but the right grease used in the bearing ensures their reliability and excellent surface protection.

Tasks of grease for electric motor bearings:

Electric motor bearing grease has several key functions:

- Reduces friction and wear: Lubricant reduces friction between bearing components, allowing the engine to run smoother.

- Corrosion protection: The grease protects bearings against corrosion, especially in humid or aggressive environments.

- Seal: The grease acts as a seal, preventing contaminants from entering the bearing.

Choosing an Electric Motor Lubricant

Electric motor grease should provide long-term lubrication over a wide temperature range. It should contain performance-enhancing additives, providing good oxidation and wear resistance, and low oil migration.

There are a number of specific challenges and requirements in many applications that will help in selecting the best synthetic grease for your electric motor setup.

Here are some properties to consider when choosing a lubricant for an electric motor:

Viscosity:

The oil viscosity should be appropriate for the load and speed of the engine at operating temperature. Typical mineral oil viscosity in electric motor lubricant is approximately 90-120 cSt @40°C .

Consistency:

For motors with a horizontal shaft configuration, NLGI 2 greases are typically used, and for motors with a vertical shaft, NLGI 3 greases are typically used.

Oxidation resistance:

Grease for electric motors should have high resistance to oxidation.

It is important that any grease or lubricant avoid oxidation. This is especially important in industrial electric motor and fan motor systems where high temperatures can lead to oxidation of fluids and the build-up of deposits on bearing surfaces from cheaper fluids. The build-up of this gum or gunk can increase motor temperatures, impact performance and ultimately lead to motor bearings sticking, seizing or completely failing.

A good indication of oxidation resistance is the ASTM D3336 high temperature test results.

Corrosion resistance

Rust, oxidation or corrosion occurs when the surface of iron or steel is exposed to moisture and oxygen, forming an oxide deposit. The build-up of oxide deforms the surface of the metal and weakens the structure of the metal, and over time this weakening takes its toll and can lead to cracks and bearing failures in equipment.

Greases provide additional corrosion resistance through advanced additive technology. They better protect and lubricate your system from rust and corrosion in wet or humid environments.

Dropping point:

The dropping point is the temperature at which the grease dissolves or the oil separates from the thickener. A grease with a high dropping point is desirable because of the high temperatures reached by the electric motor bearing. The desired dropping point is 200'C and above.

Temperature range and thermal stability:

One of the most important factors to consider is operating temperatures. If the grease you choose has poor stability at low or high temperatures, this could mean that you will be forced to relubricate your bearings much more often or, in the worst case, replace them due to failure.

Electric motor bearing grease should not soften by more than NLGI grade 1 on the ASTM cone penetrometer test, which measures the consistency of the grease after 100,000 strokes.

|

Type of grease |

NLGI Grade |

Base Oil Chemistry |

Compaction system |

Operating temperature range |

| MOLYKOTE® G-0010 Bearing Grease |

2 |

Mineral oil |

Modern polyurea |

-30°C to 170°C |

| MOLYKOTE® BG-555 Low Noise Grease |

2 |

Synthetic ester |

Lithium complex |

-40°C to 150°C |

| MOLYKOTE® G-2001 |

2 |

Synthetic PAO |

Lithium Calcium |

-40°C to 204°C |

| MOLYKOTE® 44 medium |

2 |

Silicone oil |

Lithium |

-50°C to 130°C |

|

MOLYKOTE® G-3500 |

2 |

Polyalkylene glycol (PAG) |

Lithium with PTFE |

-40°C to 150°C |

| SKF LGHQ2 | 2 |

Mineral oil |

Diurea | -30 to +160°C |

Below is a list of lubricant products dedicated to electric motors: