Silicone lubricant mixtures

Sort + Filter

What is silicone lubricant compound?

Silicone compounds are special grease-like compounds that are resistant to oxidation and thermal degradation, as well as high temperatures, moisture and many chemicals. They also resist shrinkage when dry, making them a good choice as a sealant and lubricant in a variety of applications.

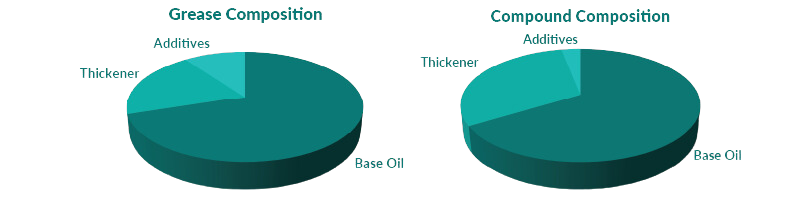

Grease compounds are unique compounds, versatile solutions for lubrication and protection where conventional grease does not or cannot perform. The basic formulation of any grease or compound consists of a lubricating base oil, a thickener system and a range of specialist additives to enhance and tailor performance for a specific application.

| Lubricant composition | In typical greases | In silicone compound mixtures |

| Base oil | 65% - 90% | 65% (always silicone fluid) |

| Thickener | 10% - 30% | 30% (typically silica) |

| Extras | 0% - 10% | 0% - 3% |

What to choose silicone grease or silicone mixture?

When the chemical composition of the compound and grease are so similar, how can you be sure you’re choosing the right one for your device? Here’s a quick cheat sheet to help you highlight the benefits of both types of grease.

|

Benefits of grease |

Advantages of silicone mixture |

|

|

Applications of silicone compounds

Compound lubricants are ideal for a wide range of specialized equipment and applications where moisture or electricity are present. Silicone compounds can provide exceptional performance in applications such as:

- Moisture-resistant barrier on electrical plugs or equipment

- Dielectric insulator or grease in high current switches

- Anti-adhesive agent for plastic and metal surfaces

- Processing the mold to release

- O-ring and valve grease at ambient or high temperatures

- Sealant for vacuum and pressure systems (HVG)

- Applications meeting NSF, FDA or USDA requirements such as NSF 61 for use in the food and beverage industry as well as drinking water applications

- Dual purpose greases and sealants on valve seals and seats,